MAM HPPS – High Performance Paletten System

The high-performance pallet system HPPS with its components can clearly be assigned to the tooling machines family and is adapted to customer requirements on a project-specific basis. The heart is the PLC of the MAM robot, which is controlled by an automation computer without moving parts.

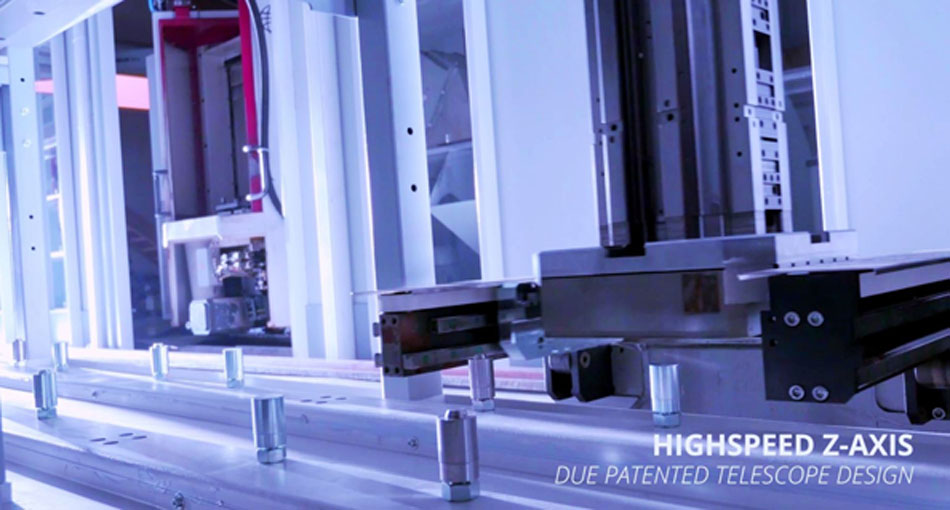

Durability and constant efficiency

A solid welded steel frame, helical racks, linear guides, servomotors, a very low center of gravity and the patented pallet carrier allow accelerations of up to 10 m/s² and final speeds of 4 m/s, even at high weights. This results in obvious cost advantages, even with short cycle times.

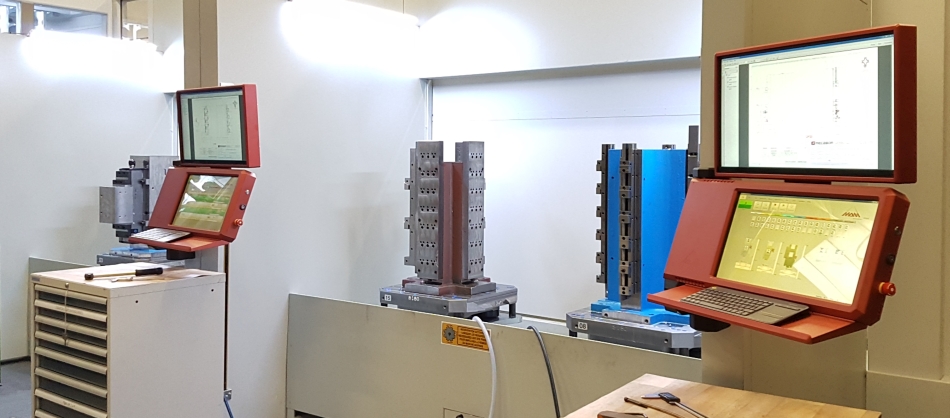

Double loading station – optimum assembly and clamping

Each loading station can be used to load pallets as well as material-boxes without prior modification. The protection is provided by the light grid with a clearly visible open/close status. MAM’s high-performance pallet systems can be combined with almost any machine type.

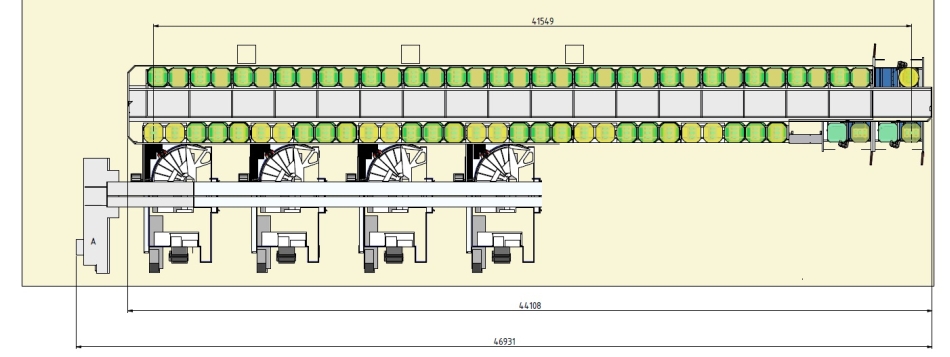

Modularly expandable – optimal use of space

The HPPS series is available in 2, 3, 4 or 5 levels. The basic module starts with 6 pallet slots, i.e. 12 storage slots as standard. The overview shows the standard dimensions. Thanks to the parameterized 3D design, the storage space can be modified to specific sizes; in length, width and height.

The wide variety of high performance pallet systems allows MAM to provide always an optimal solution.

| SIZES | PALLET SIZE (mm) | PIECE SIZE (mm) | TRANSFER WEIGHT (kg) |

|---|---|---|---|

| HPPS-4 | 400×400 | Ø630 | 750 |

| HPPS-5 | 500×500 | Ø800 | 1000 |

| HPPS-6 | 630×630 | Ø1100 | 1500 |

| HPPS-8 | 800×800 | Ø1300 | 2200 |

| HPPS-10 | 1000×1000 | Ø1500 | 3000 |

| HPPS-12 | 1200×1200 | Ø2000 | 5000 |

| HPPS-16 | 1600×1600 | 2000 x 3000 | 7500 |

| HPPS-20 | 2000×1250 | Ø2500 x 1500 | 6000 |

| HPPS-30 | 3000×1250 | 3500 x 1500 | 6000 |

MAM’s high-performance pallet systems can be combined with almost all machine types.

Take a look at our collection of examples of these system solutions.

All production phases under control thanks to high storage density

Lack of space always plays a role. Compact design and adapted linear robots create space for further pallet levels, where others are already bumping their heads. Where previously a machining center without a pallet system has stood, a new machine with a MAM HPPS could be there instead.

Simple operation and all status information at a glance

The intuitive design of the Production Organizer makes it easy to use in real time, without requiring much training, because the System is divided into individual to-do lists, that everyone understands. Dynamic production control enables forecasts of the entire order planning of all machines and resources according to delivery date or priority.