Find your Pallet Automation System. Different requirements demand different accesses.

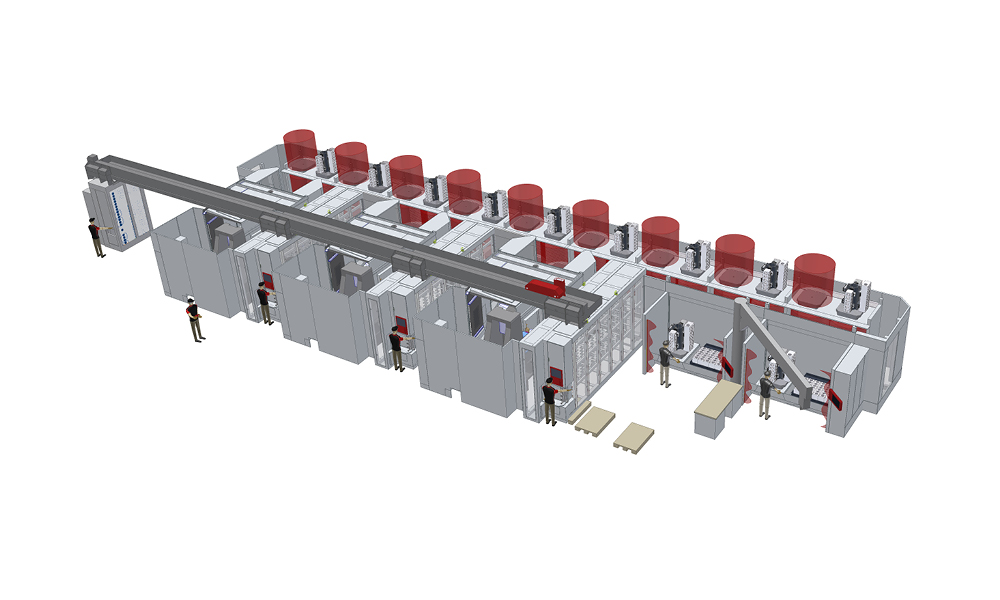

A system that links several machines together and also is able to produce unmanned at weekends? Well-coordinated machining processes – different batch sizes for major customers and always an eye on unit costs and throughput times – after all, process cost optimization is your constant companion.

Find yourself in High Performance Pallet System

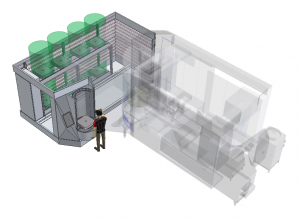

A new machine is coming, or the already run-in one needs a retro-fit? As a precision parts manufacturer with a wide variety of rapidly changing NC programs, you are looking for additional capacities and simple, transparent handling with the necessary resource planning to have always rush orders under control.

Applies? Compact Pallet System

Extreme lack of space and yet you need 16 pallet places or more for your 4- or 5-axis horizontal machining center and maybe your workpiece weights will increase in the future. This pallet system can be used where it was not considered possible.

Could match with my machine! Rotary Pallet Changer FX

Good reasons for your automation

Automate versus expand: Faster implementation of automation results in shorter payback times and a higher return on investment. The investment in the existing good machine and not in the expansion of the machinery, not only makes it financially easier, but one also remains flexible.

Finding suitable experts is becoming increasingly difficult. This forces companies to think about alternatives.

High order pressure and at the same time the realization of a better operating grade also requires more spindle hours and leads to unmanned production.